PE block-bottom valve bags are manufactured from mono or coextruded and blown-to-size polyethylene tube by cutting and fastening on AD-plastic production lines. These bags can be printed, embossed and/or perforated.

Print can be ordered with state-of-the-art printing results, achieved with flexo-printing on one or two sides in up to 4 colors, and the top and bottom patches can be printed as well.

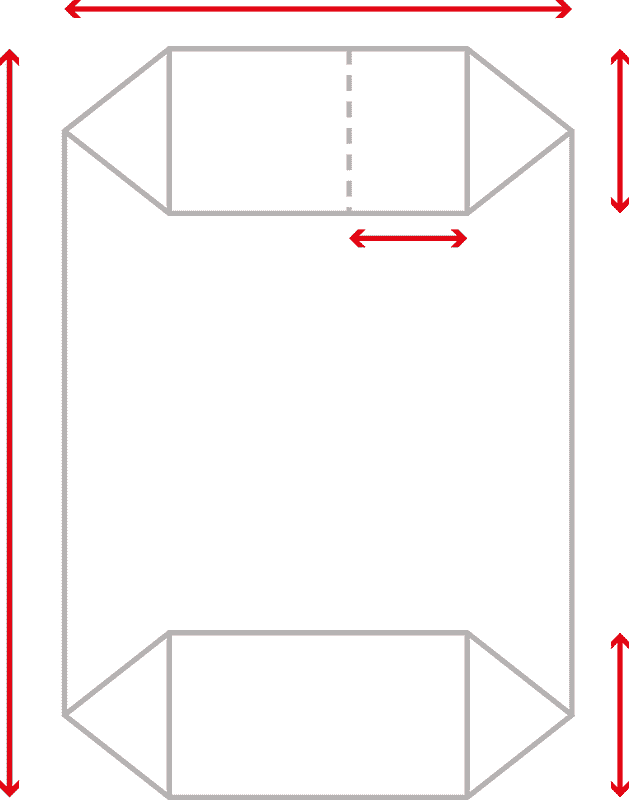

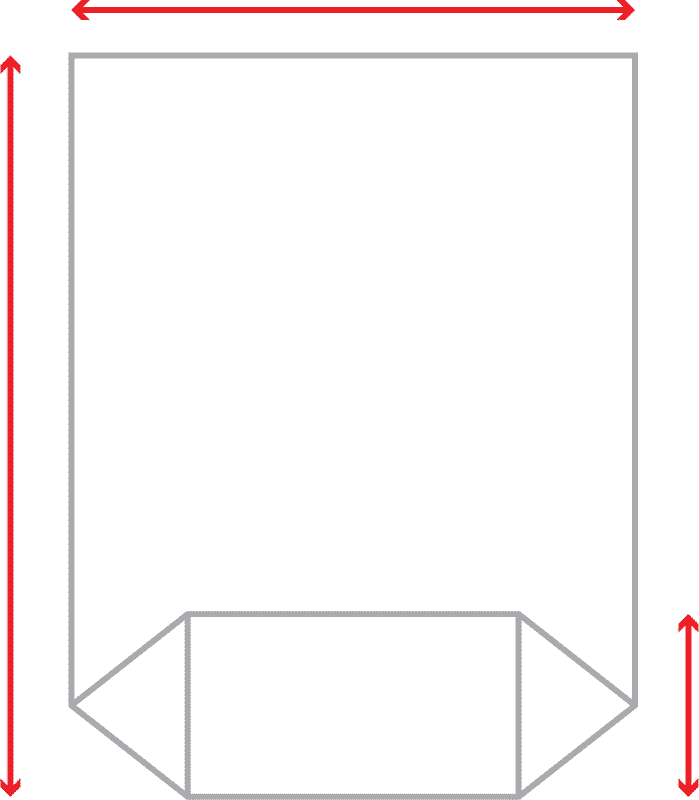

The bottom, top and valve are formed by folding.

Our PE bags have excellent tensile strength and are resistant to chemicals and equipped to perform in different environments.

The bags are extremely suitable for the packaging of many different kinds of materials. For use in the food industry the bags are UN-certified and are supplied in food-approved quality. They can also be used for the packaging of dangerous materials.

Size

Range is from 370x400x110 mm

to 600x820x180 mm (valve bag)

to 600x900x180 mm (open mouth bag)

Width: 350 – 600 mm

Length: 400 – 940 mm

Bottom/Top: 90 – 180 mm

Thickness: 120-200 µ in mono and coextruded quality

Embossing: 2-2 stripes, 50,80,100 mm